An Advanced Sprayed Porous Polymer Separator Coating That Encapsulates the Entire Electrode Surface

The Nuvola SafeCoat™ Direct Deposition Separator (DDS) product is a drop-in solution for lithium-ion batteries (LIB) that replaces conventional film separators with a porous polymer coating sprayed directly on the entire electrode surface. SafeCoat DDS is compatible with manufacturing techniques used in LIB factories worldwide. The advanced Nuvola separator product is battery chemistry agnostic and designed to work with conventional and emerging electrode chemistries. Porosity, wettability, ionic conductivity, temperature range, and other key specifications are highly competitive with premium separator materials in the market today. Unlike traditional film separator material, with SafeCoat DDS, battery performance-critical characteristics are each precisely tuned to the manufacturer's battery chemistry, electrode material, and application requirements.

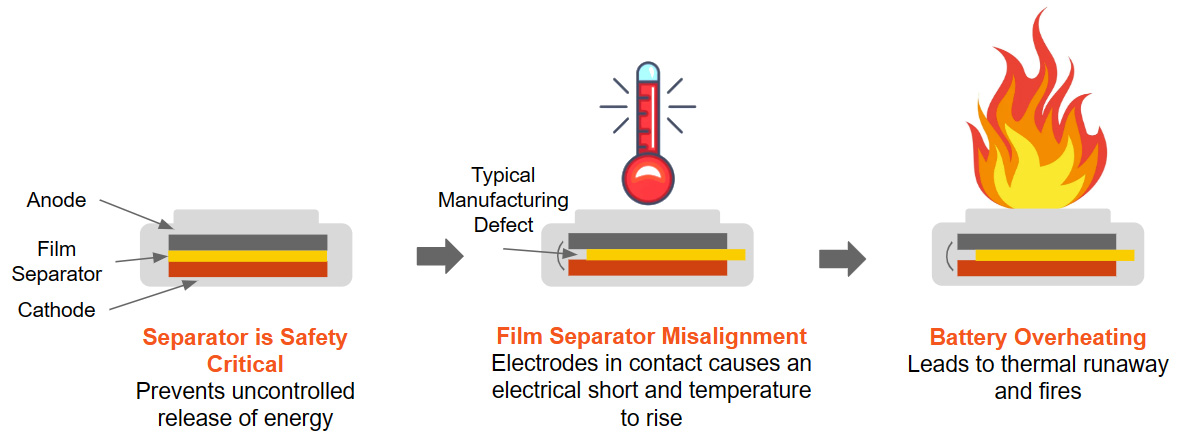

A Real Solution to the Battery Thermal Runaway Safety Issue

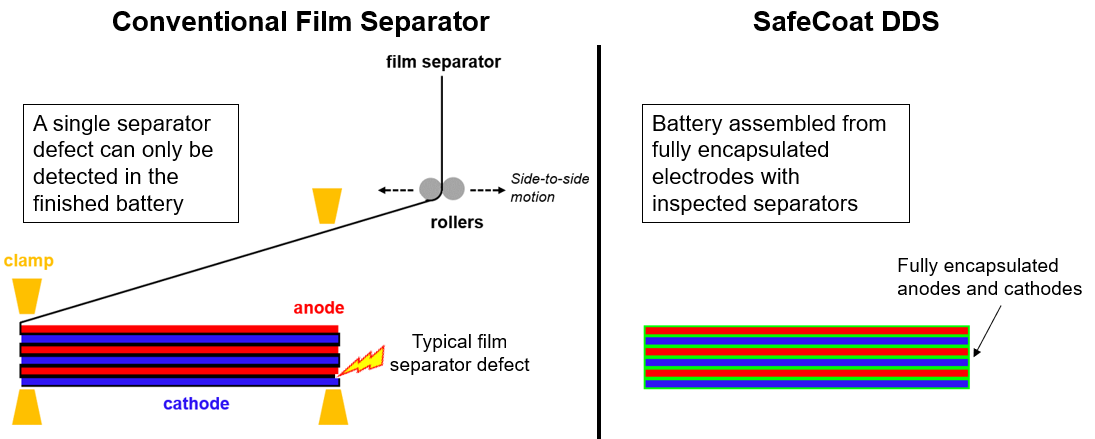

Eliminates mechanical film separator stacking tools that can misalign, misfold, and tear traditional separator material, the primary cause of battery defects creating internal shorts, thermal runaway, and battery fires.

Eliminating Expensive Defects Decreasing Scrap Rate by 99%

Most defects in batteries using traditional film separator materials can only be detected when the battery is fully assembled. When film separator defects are found, the entire fully-assembled cell must be scrapped. With an estimated decrease in separator stage assembly defects of 99%, a rare battery defect can be reworked and corrected at the individual electrode level – a huge reduction in scrap battery costs.

More Volume For Active Material Improves Battery Energy Density

up to 20%

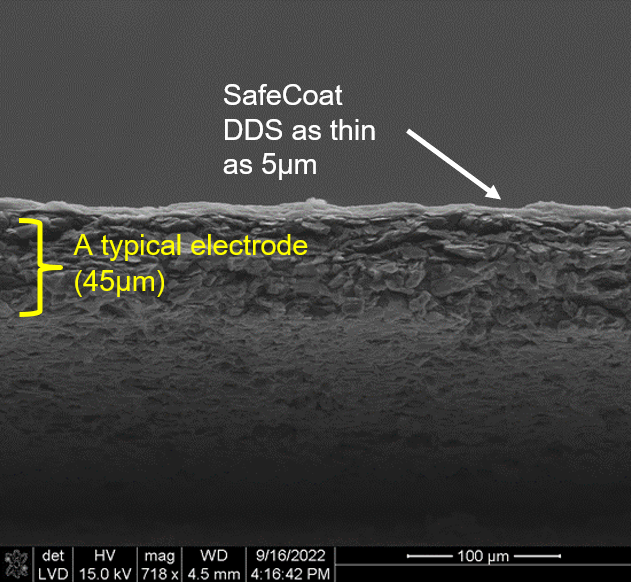

The hundreds of plastic film separator folds used in an EV battery do not store lithium ions – but consume a significant amount of battery volume. Decreasing the thickness of the separator from the plastic separator film’s 20µm to SafeCoat’s ultra-thin 5µm layer leaves more room for active material – without sacrificing battery performance. Batteries using Nuvola's SafeCoat DDS technology can expect an energy density improvement of up to 20% in the same physical space.

Eliminates the Error Prone High-Speed Z-Fold Assembly Issue

Increasing battery build rates by running the Z-fold plastic separator stacking equipment at higher and higher speeds has significant negative yield tradeoffs. Errors in Z-fold mechanical accuracy, repeatability, tears, misalignments, and stretching are just a few of the issues that occur as the fold rate increases. Using SafeCoat DDS coating and eliminating plastic separator film speeds production, eliminating these manufacturing errors.