Nuvola Technology is commercializing SafeCoat, the world's first Direct Deposition Separator (DDS) platform that replaces conventional film separators with a sprayed-on porous polymer layer. SafeCoat provides the same ionic and power performance with vastly superior thermal properties. By eliminating troublesome freestanding separators, SafeCoat radically simplifies the assembly of battery cells for consumer, medical, EV and ESS applications.

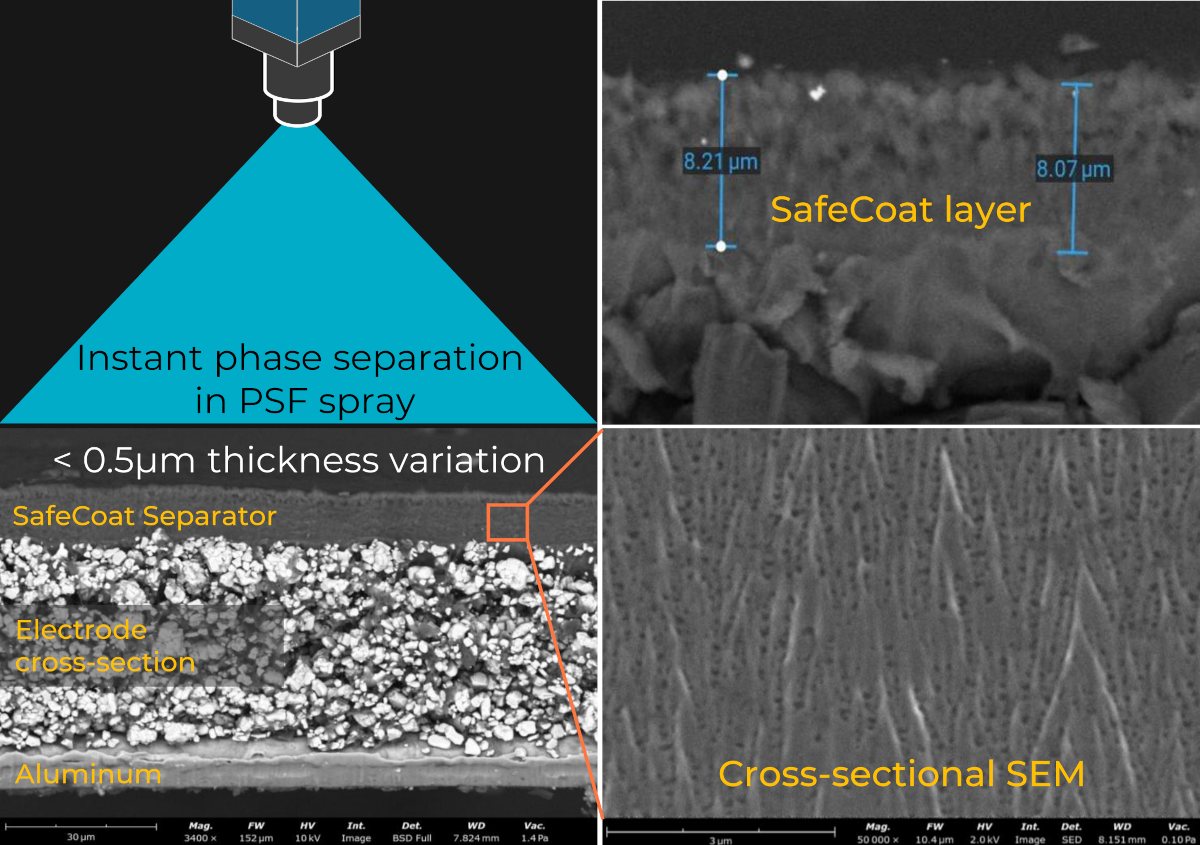

Instant Phase Separation

for Spray-On Battery Separator

SafeCoat DDS leverages the world’s first instant phase separation process to produce ultra-uniform, defect-free separator layers.

- Separator Material: PSF (Polymer Separator Fluid) is 100% polymer formulation that is entirely liquid, free of undissolved particles, ensuring highly uniform spray without nozzle clogging.

- Separator Formation: SafeCoat DDS (Direct Deposition Separator) deposited instantly through phase separation from PSF spray, forming a thin, uniform porous separator layer that fully encapsulates the electrode surface and edges.

- High-Speed Production: This patent-protected process is ideal for mass production that reduces production time and cost, while enhancing separator performance.

- Customizability: Pore size and thickness are tunable via engineered PSF composition and phase separation design, enabling compatibility with any battery chemistry.

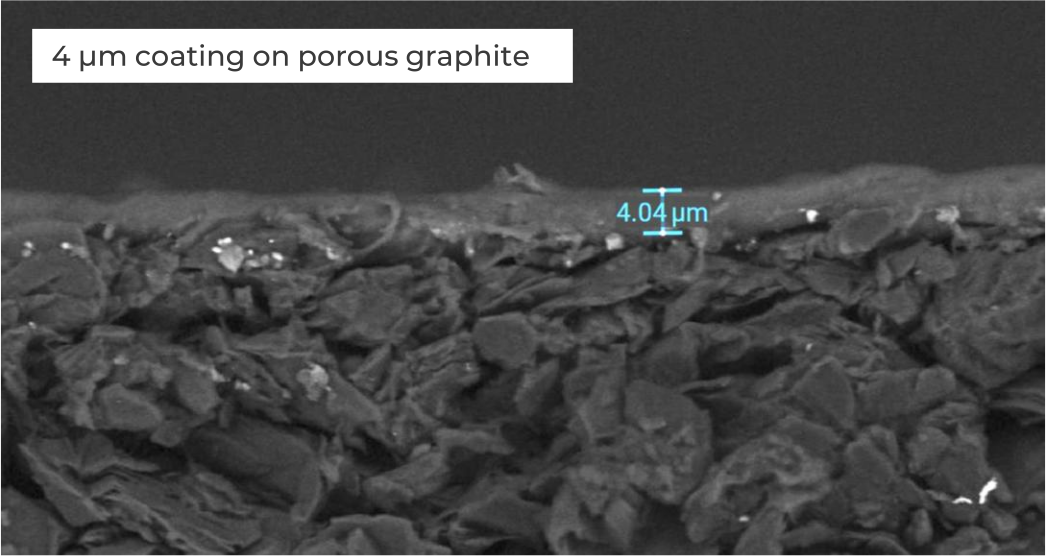

High Energy Density Achieved with

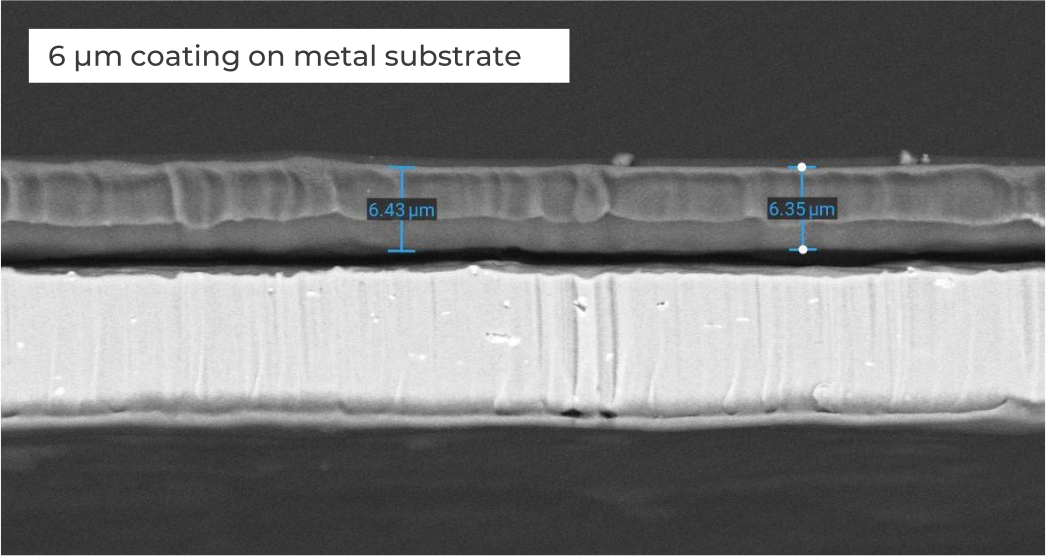

Ultra-Thin Nanoporous Separator Layer

Hundreds of conventional film separator folds in an EV battery do not store lithium ions. Instead, they consume valuable space. SafeCoat’s ultra-thin layer frees more volume for active material, improving energy density by up to 10%.

Uniform Nanoporous Structure: Thin SafeCoat layer with precisely controlled nanopores delivers superior ion conductivity, enabling faster lithium-ion transport and high electrochemical performance.

Excellent Adhesion to Electrode: Unlike freestanding films that wrinkle, tear, or fold when made ultra-thin, SafeCoat is applied directly onto the electrode surface, enabling stable, defect-free thin layers.

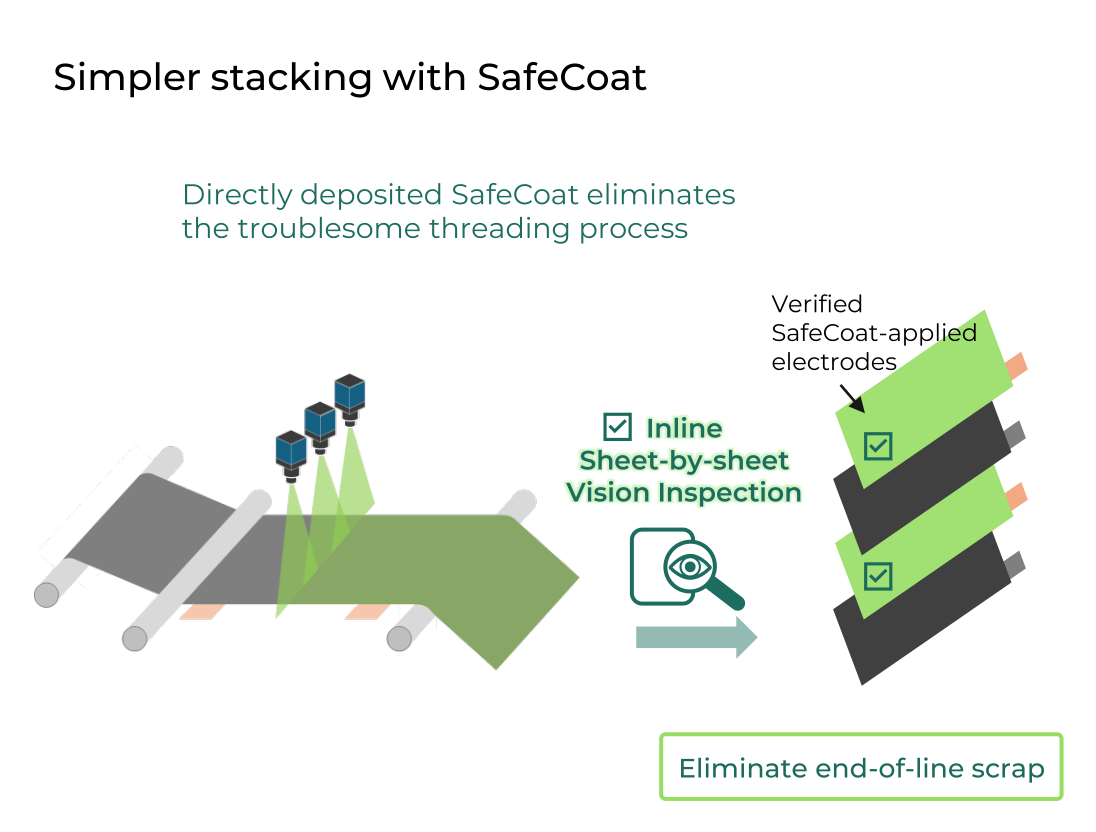

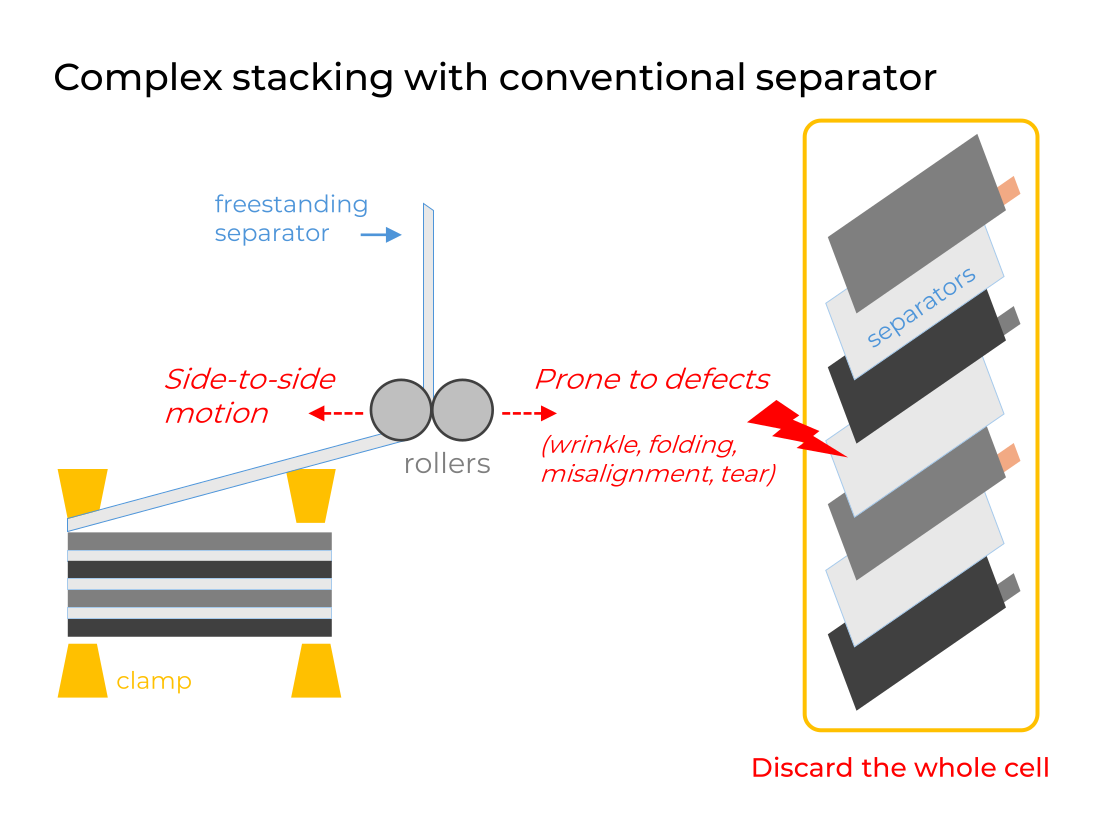

Cost Reduction via SafeCoat’s

Threading-Free, Film-Free Assembly

Conventional separators require delicate mechanical assembly, which can result in separator wrinkles, tears, and misalignment that lower manufacturing yield and lead to cell underperformance.

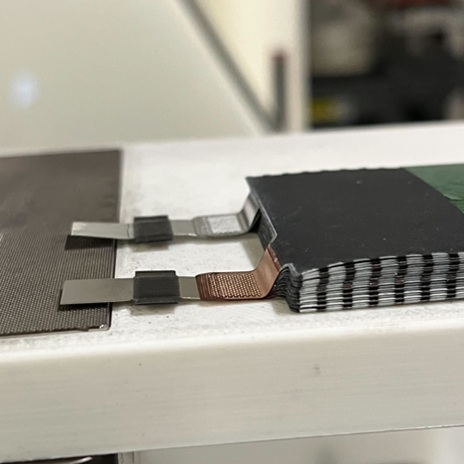

SafeCoat DDS deposits adherent separator layers directly onto the electrodes, using high-speed roll-to-roll processing equipment that is fully compatible with battery factories planned and in operation. Individual separator-applied electrodes are verified before cell assembly and the cell assembly process is simplified, improving yield and driving down costs for manufacturers.

SafeCoat DDS film-free stacking

Conventional Z-fold stacking

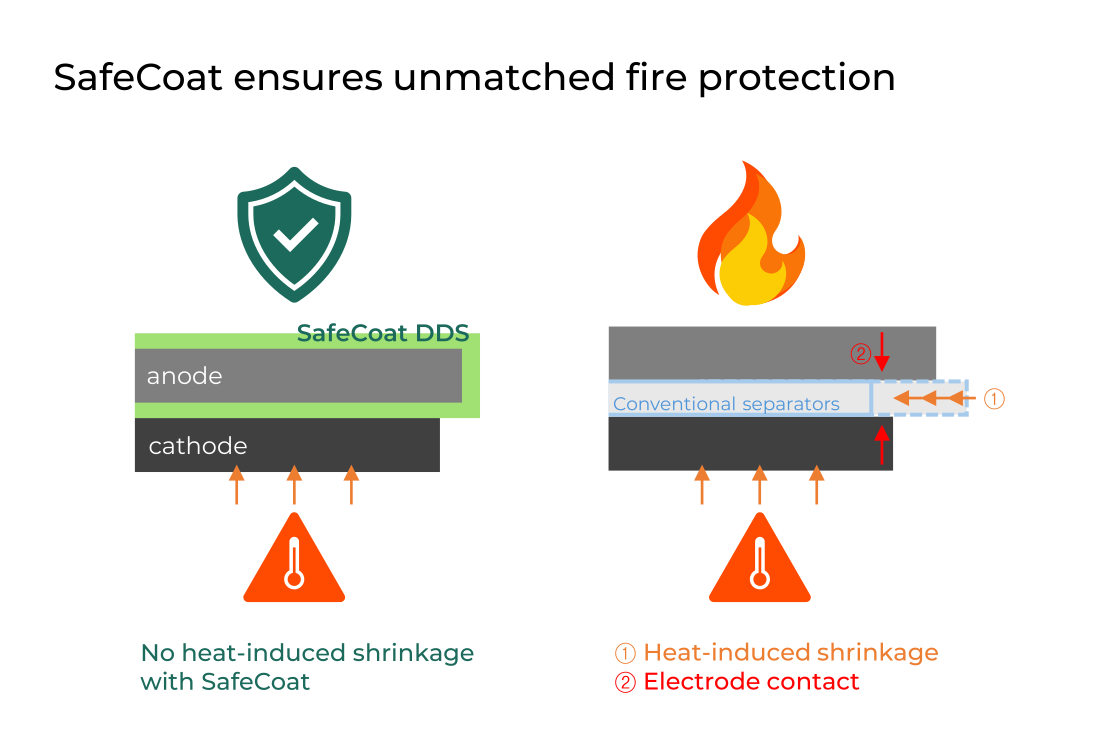

SafeCoat™ DDS: Redefining Battery Safety from the Inside Out

Separator is crucial in preventing thermal runaway, and must maintain effective electrical insulation of the electrodes in the event of battery damage or failure. Conventional separators are produced by mechanical extrusion, leading to residual stress in the film and shrinkage at temperatures exceeding 100dC, which can cause direct contact between the electrodes and accelerate thermal runaway.

Thanks to our groundbreaking in-situ pore formation method, SafeCoat DDS layers do not contain residual stress. This feature, coupled with strong adhesion to the electrodes' surfaces and edges, allows SafeCoat to survive exposure up to 220oC with 0% shrinkage. SafeCoat has even been demonstrated to maintain insulating properties in contact with molten lithium metal.

Flammability Test

Comparing SafeCoat DDS with Traditional Film Separator

SafeCoat DDS: No shrinkage under flame

Film separator: Immediate shrinkage & tearing