SafeCoat DDS in Pouch Cells

Proven Performance from Consumers to EV-Scale

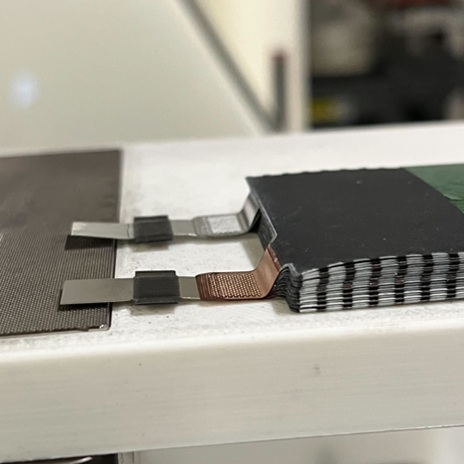

SafeCoat™ DDS has been validated in large-format pouch cells, confirming that the same performance advantages observed in coin cells scale seamlessly to EV-relevant formats. Builds up to 5 Ah demonstrated consistent cycling, high coating uniformity, and stable performance, reinforcing SafeCoat’s readiness for mass production.

- Validated Scalability: From 0.2 Ah to 5 Ah pouch cells, SafeCoat maintained coating quality and stable cycling.

- Consistent Performance: Even in unoptimized, additive-free builds, SafeCoat delivered state-of-the-art results.

- Safety & Thinness: Ongoing tests confirm thermal stability and safe operation, with thin coatings down to 10 µm under evaluation.

- OEM-Verified Results: Partner OEMs are achieving strong results with SafeCoat across their optimized chemistries, confirming both compatibility and superior properties.

We continue to validate SafeCoat directly with customers, bringing the flexibility to adapt at the customer site and meet their specific requirements. Looking ahead, SafeCoat is being prepared to support future battery needs across materials, chemistries, and cell formats, ensuring that wherever separators are used, SafeCoat can deliver.

SafeCoat Cell Nail Penetration Test Results

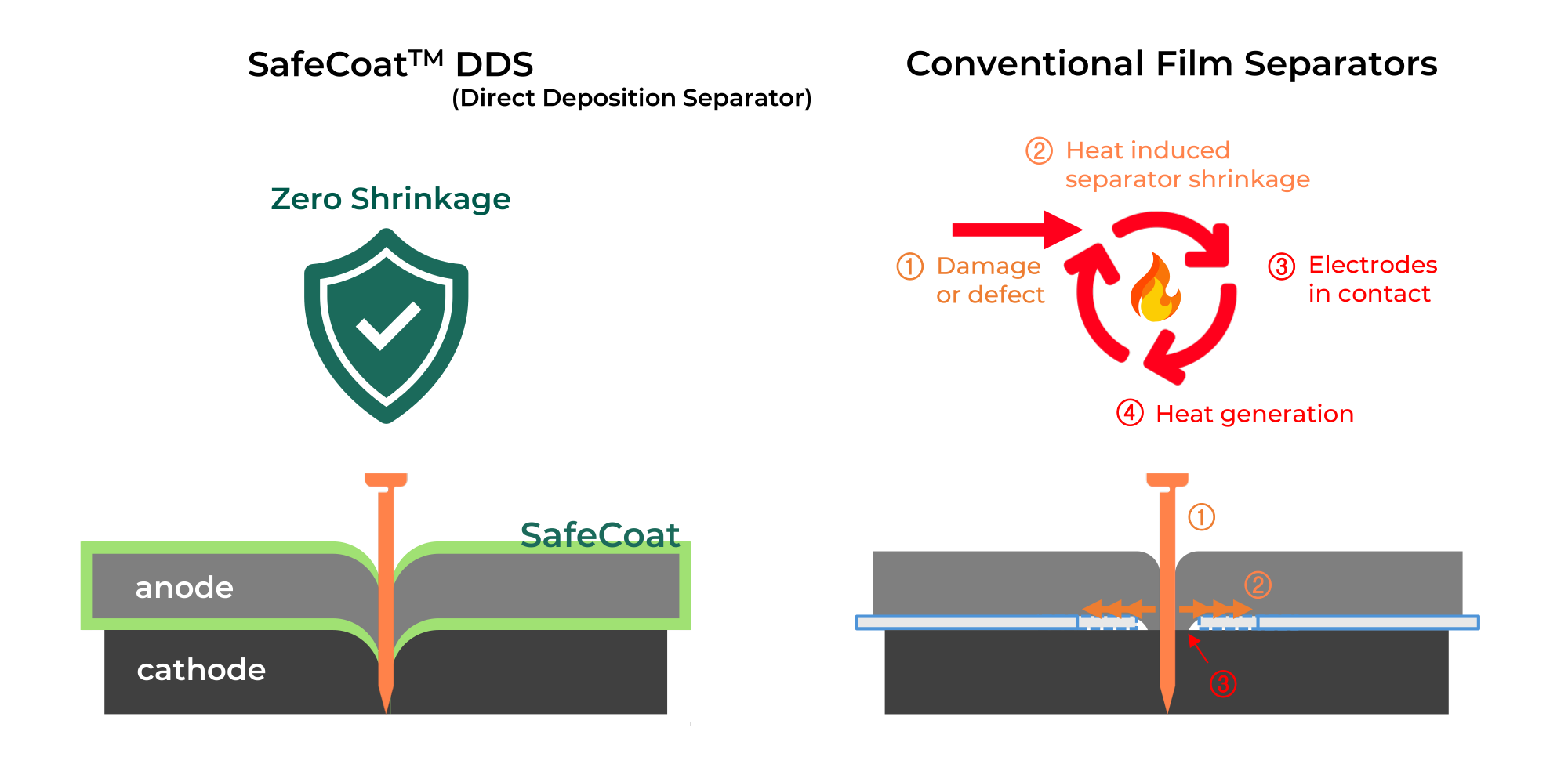

Separator with Zero Shrinkage That Stops Thermal Runaway Before It Starts

Everyone agrees that once a battery enters thermal runaway, it’s virtually unstoppable. That’s why SafeCoat is designed to eliminate the root cause of thermal runaway: direct contact between the electrodes.

When conventional separators are exposed to heat generated by damage or a manufacturing defect, they shrink leading to immediate and highly exothermic reaction between the charged electrodes. SafeCoat resiliently remains adhered to the electrodes, and does not shrink when heated. The cycle of “heat generation → separator shrinkage” acceleration is prevented from beginning.

Latest Technical Update: SafeCoat Pilot Cells

Dual Innovation in Microbatteries

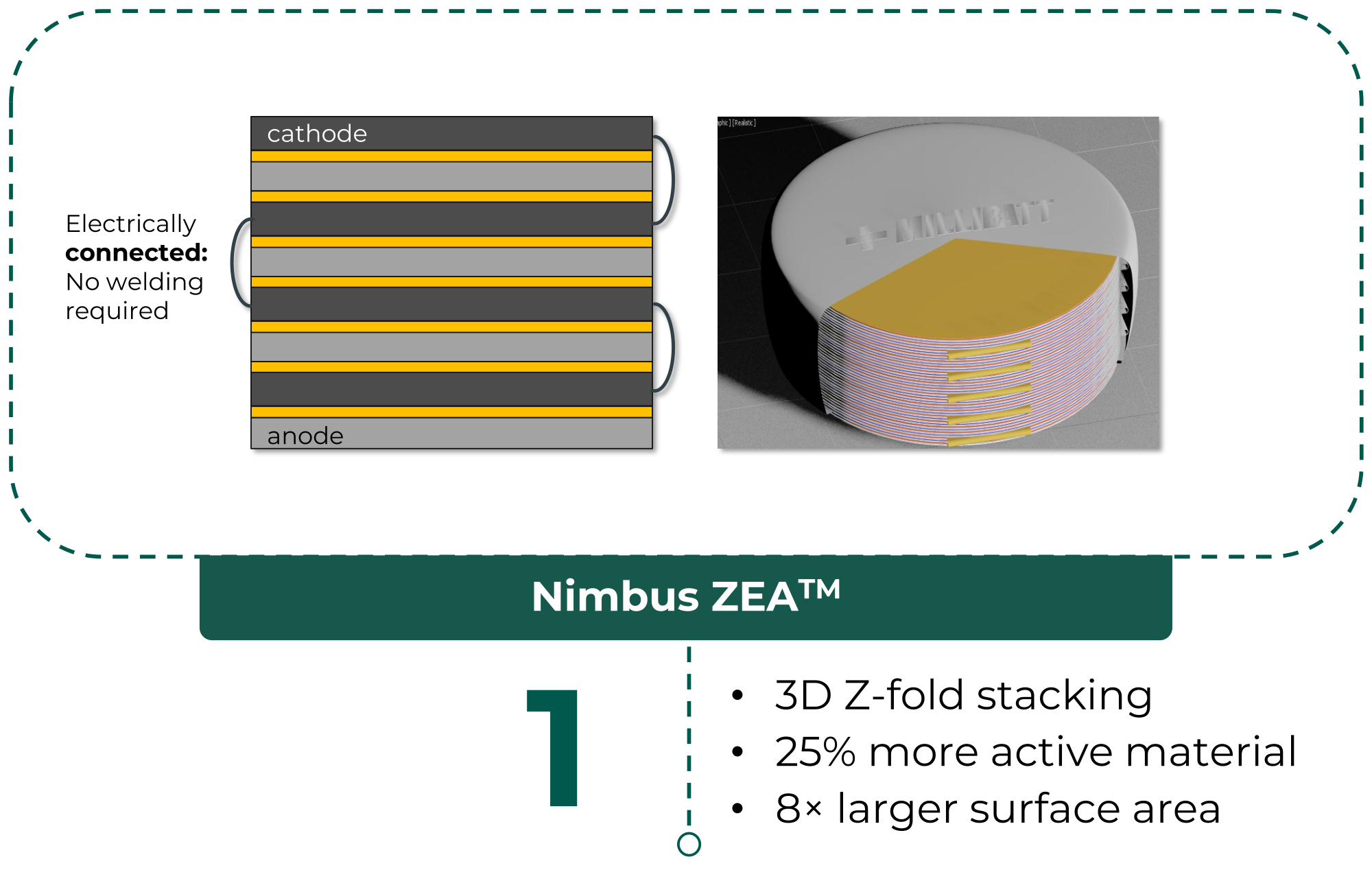

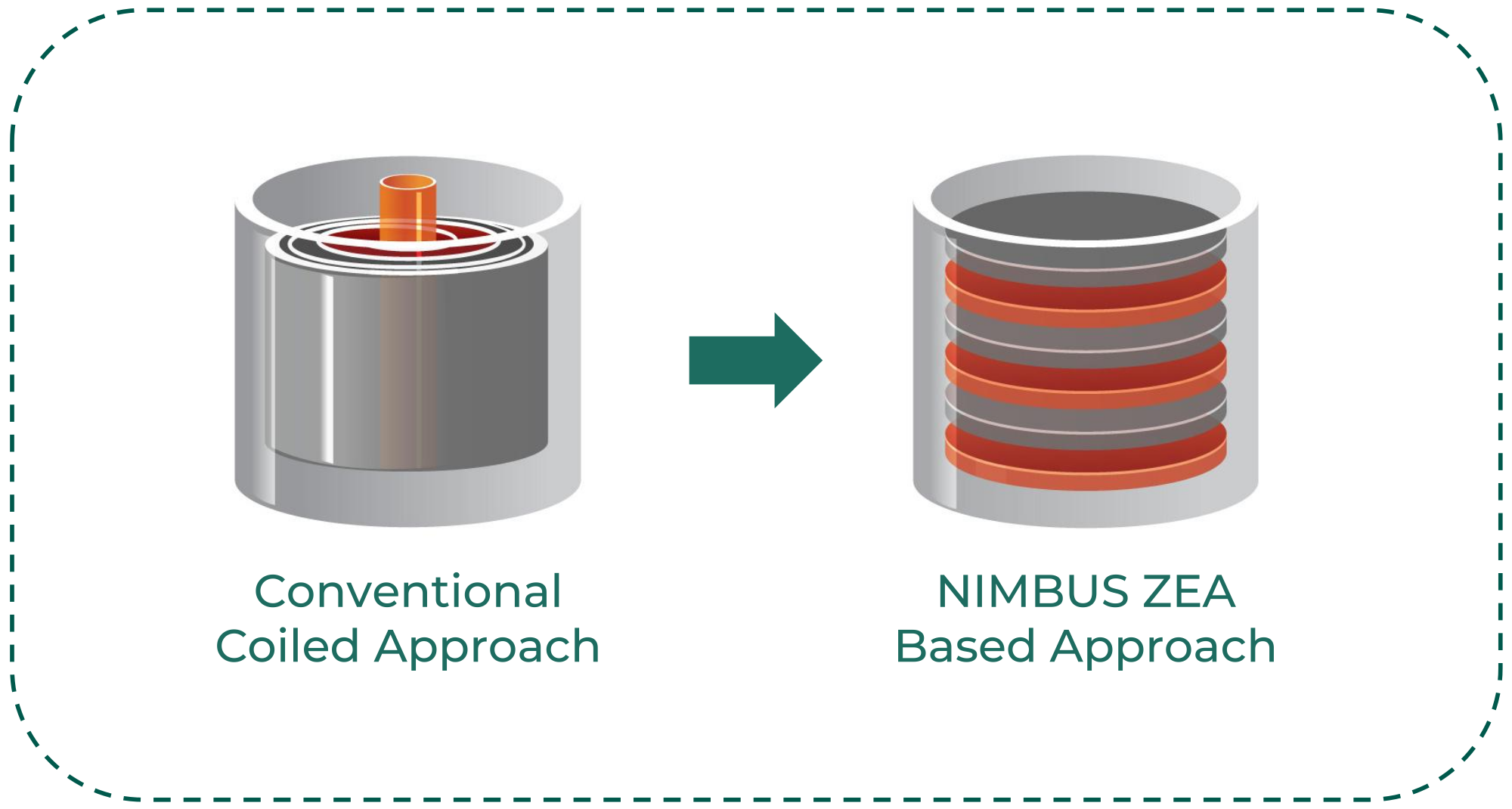

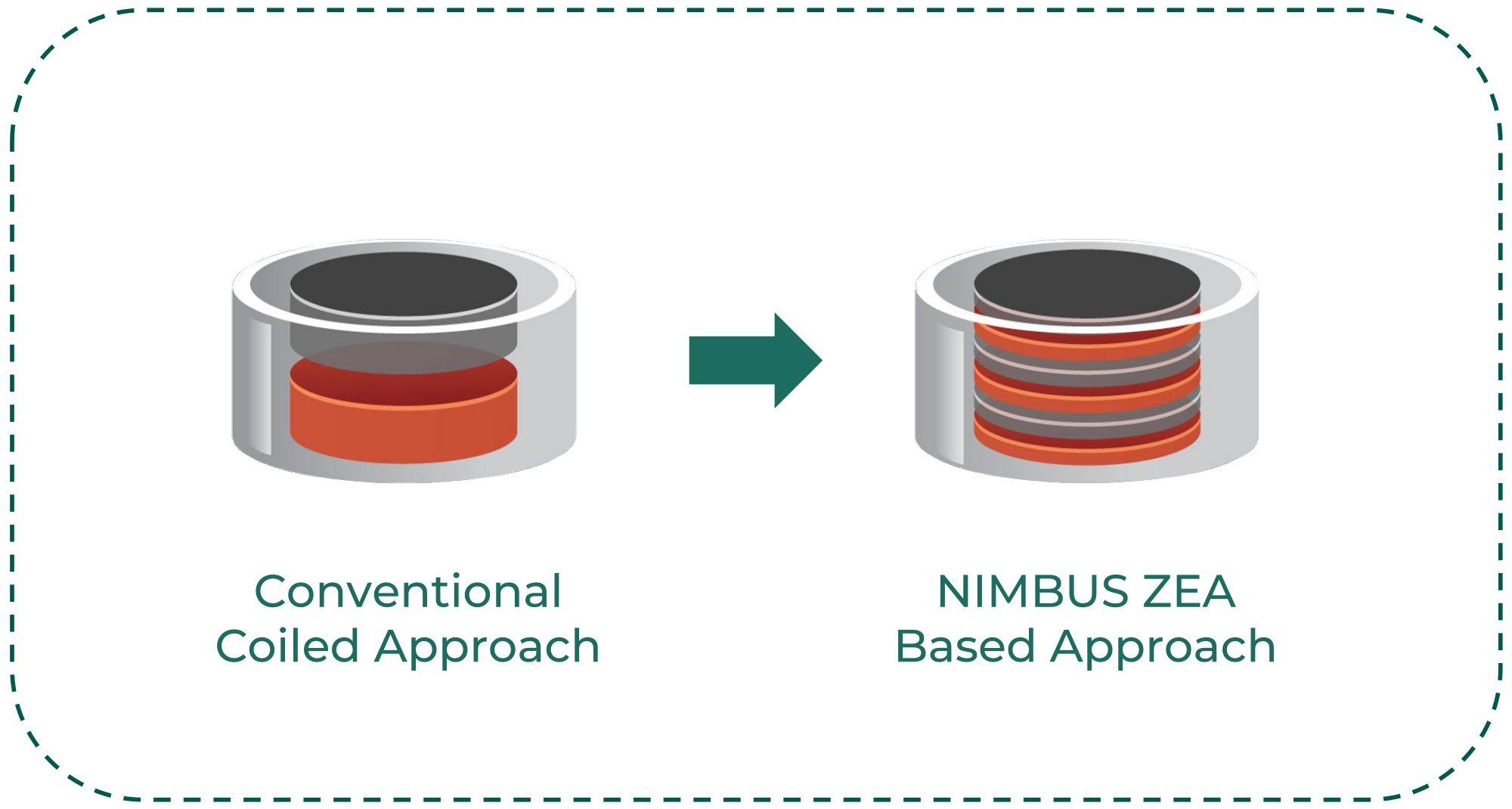

Nimbus ZEATM (Z-Fold Electrode Architecture) + SafeCoatTM DDS

In pursuit of more energy-dense small batteries, Nuvola engineers developed the Nimbus ZEA™, powering applications such as TWS earbuds, hearing aids, and wireless IoT sensors.

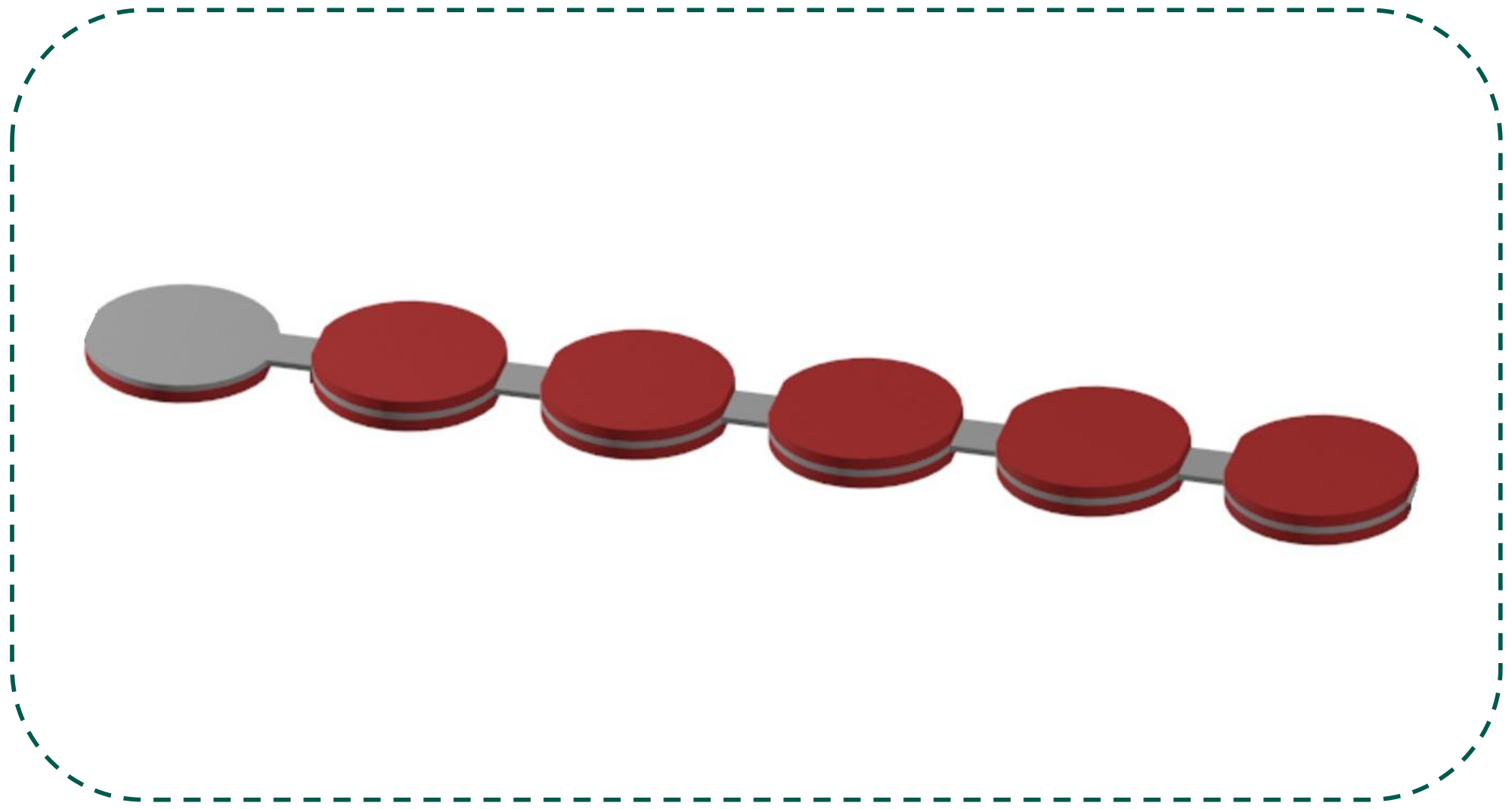

Z-folded electrode architecture, enabled by SafeCoat™ separator, provides more energy in a cylindrical can, while working for previously unobtainable electrode shapes and stack thickness.

25% More Active Material

from improved internal space utilization with stacked electrodes

16× Longer Bluetooth Connectivity

high surge current support enabled by 8× larger electrode surface area

25% Longer Run Time

enabled by flat electrodes with higher active material loading

Flexible for Next-Gen Wearables

compatible with non-circular cell designs to expand application possibilities

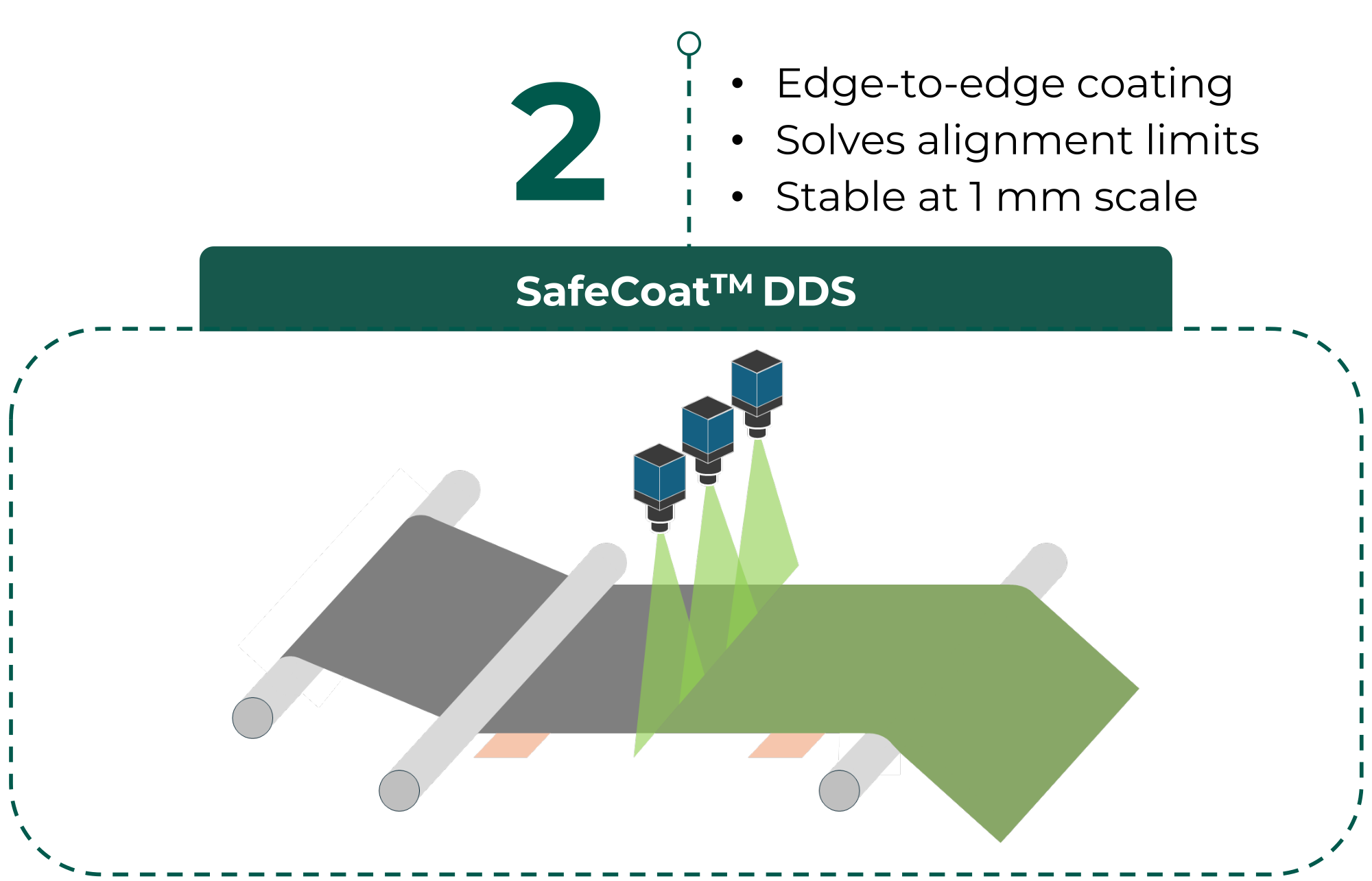

Breakthroughs Become Manufacturable

When combined with SafeCoatTM DDS, the Nimbus architecture not only achieves higher energy and power density, but also simplifies manufacturing. This is one example of how SafeCoat catalyzes innovations across formats.

SafeCoat unlocks high-precision battery manufacturing. As batteries get smaller, alignment tolerances become extremely tight, and even tiny mismatches can cripple performance. The combination of Nimbus ZEA™ and SafeCoat™ DDS enables high-yield production down to the millimeter scale.